EDWARDS Vacuum Pumps

Edwards is a global leader of vacuum and abatement and a part of the Atlas Copco Group (NASDAQ OMX Stockholm: ATCO A, ATCO B), a Sweden-based provider of industrial productivity solutions. We are proud to lead the industry, pushing the boundaries of science to deliver innovative products which are intrinsic to everyday life, working in partnership with our customers and continually setting new standards. With over 100 years of rich heritage, Edwards is the partner of choice for tens of thousands of customers in critical applications around the world. Vacuum is required in diverse sectors, from the generation of power to the production of steel, to the challenging environments of space simulation and high energy physics research. Everywhere you find vacuum requirements, you will find Edwards leading the way. From medicines to mobile phones, from computers to coffee beans, to cars and chemicals, we pride ourselves in making a difference to people’s lives. And we do it responsibly, ensuring that we innovate sustainably, whilst helping our customers to maintain their competitive advantage and operational excellence.

Custom Engineered Products End-to-end turnkey projects for process improvement

Our Custom Engineered Products (CEP) group, evolved from the acquisition of Hick Hargreaves, can provide you with equipment and turnkey services for your oil and gas, petrochemical, power generation, CPI and associated industry applications. Our services include process and mechanical design, development, project management and installation of multi-stage systems.

Steam Ejector Vacuum Systems

We can help you to replace your single stage ejector systems with multi-stage systems, providing improved energy-efficiency and the capability to handle high vapour loads without the risk of cavitation. A relatively low capital cost provides an attractive return on investment. We have over 100 years of experience in the design and supply of steam ejector systems.

Our experience in steam ejector applications include:

- Refinery Vacuum Systems

- Vacuum Distillation Units

- Flash Evaporation for Seawater Desalination

- Turbine Condenser Air Extraction

- Edible Oil Processing

- Polymerisation

- Crystallisation

- Evaporative Cooling

Seawater Deaerators

Our field-proven designs for water injection seawater deaerators are based on our experience in floating production vessels, including installations on FPSO's, semi-submersibles and tension leg platforms.

You can choose between:

- Spray/pack deaerators

- Packed column deaerators

- Trace gas stripping deaerators

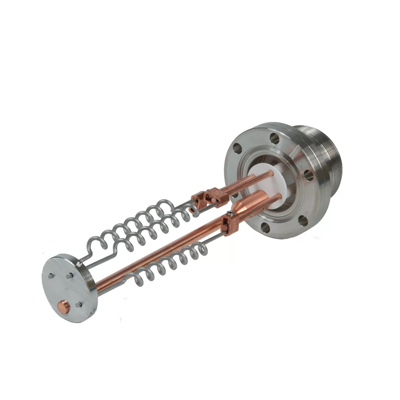

High Pressure Feedwater Heaters

We offer design and supply of replacement feedwater heaters for central power generating plants. Using designs developed by Hick Hargreaves and proven over 25 years of reliable service, our current installations are suited for modern power station operating practices. Services include replacement of vertical heaters with radiographic testing of the back face from the welded tube to tube sheet joints to ensure integrity of these critical areas.

Hybrid and Liquid Ring Vacuum Pumps

An often-overlooked process vacuum solution, we can help you to combine steam ejectors and liquid ring pumps in a hybrid pumping system designed to bring you higher efficiency and improved reliability. We have 50 years’ experience of designing and supplying these pumps to refinery and chemical plants across the globe. We can also supply engineer-to-order liquid pump systems, constructed and fabricated in materials compatible with your specific process.

iXM low energy series dry pumps can bring real process improvements with increased uptime, reduced environmental impact and cost benefits for your most critical applications.

- Energy efficient roots mechanism can reduce input power by up to 60%, reducing environmental impact and lowering cost of ownership - Gas barrier technology and thermal design improvements enable four times greater corrosion resistance than our previous series

- Advanced powder handling features deliver maximum reliability and extended pump life for multi-layer etch processes and reduced power consumption for CVD processes

- Compact and light-weight design, combined with exceptionally low noise and vibration, gives you more versatility

- Available with Xcede technology for enhanced corrosion resistance

iXH dry pump range sets new standards for harsh process capability, reliability and lower cost of ownership.

- Wide temperature range allows you to optimise the pump for minimal by-product accumulation from condensation and plating

- iXH Mk2 dry pumps provide even longer service life on the harshest of processes and can provide significant improvements in power efficiency

- Innovative pump seal technology can lengthen process life and reduce your leakage risks

- Available with Xcede technology for enhanced corrosion resistance.

iXL series is a range of low energy compact dry pumps for light duty applications such as wafer handling, PVD, and metrology.

- Fast chamber pump down and extremely low power usage

- The iXL600(N) and iXL1000(N) dry pumps are among the smallest and quietest pumps available for light duty applications

- The iXL600M and iXL1000M variants are process hardened and specially designed for dielectric (oxide) etch and other similar applications

- The iXL600(N) and iXL1000(N) dry pumps feature high pumping speed and low energy consumption