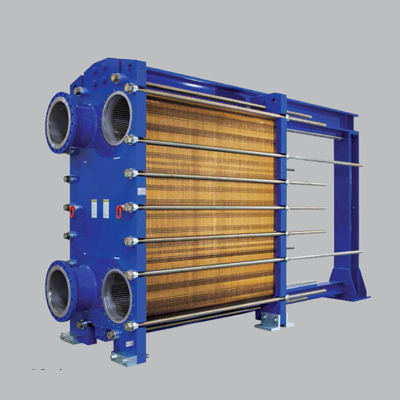

GASKETED PLATE HEAT EXCHANGERS

The gasketed plate heat exchangers reveal what passion, scientific curiosity and technological expertise can achieve. The facts: high efficiency at low operating costs, greater application possibilities at a lower investment costs. Continuous further development of the plate series targeted at the requirement of the thermo- and hydrodyn amic industries also ensure that you can achieve maximum economic efficiency. The range of plate corrugations and plate lengths enables them to be made to measure to your requirements. In addition, maintenance-friendly assembly and sealing technologies are applied, which assure the flawless seating of the gasket and plate package.

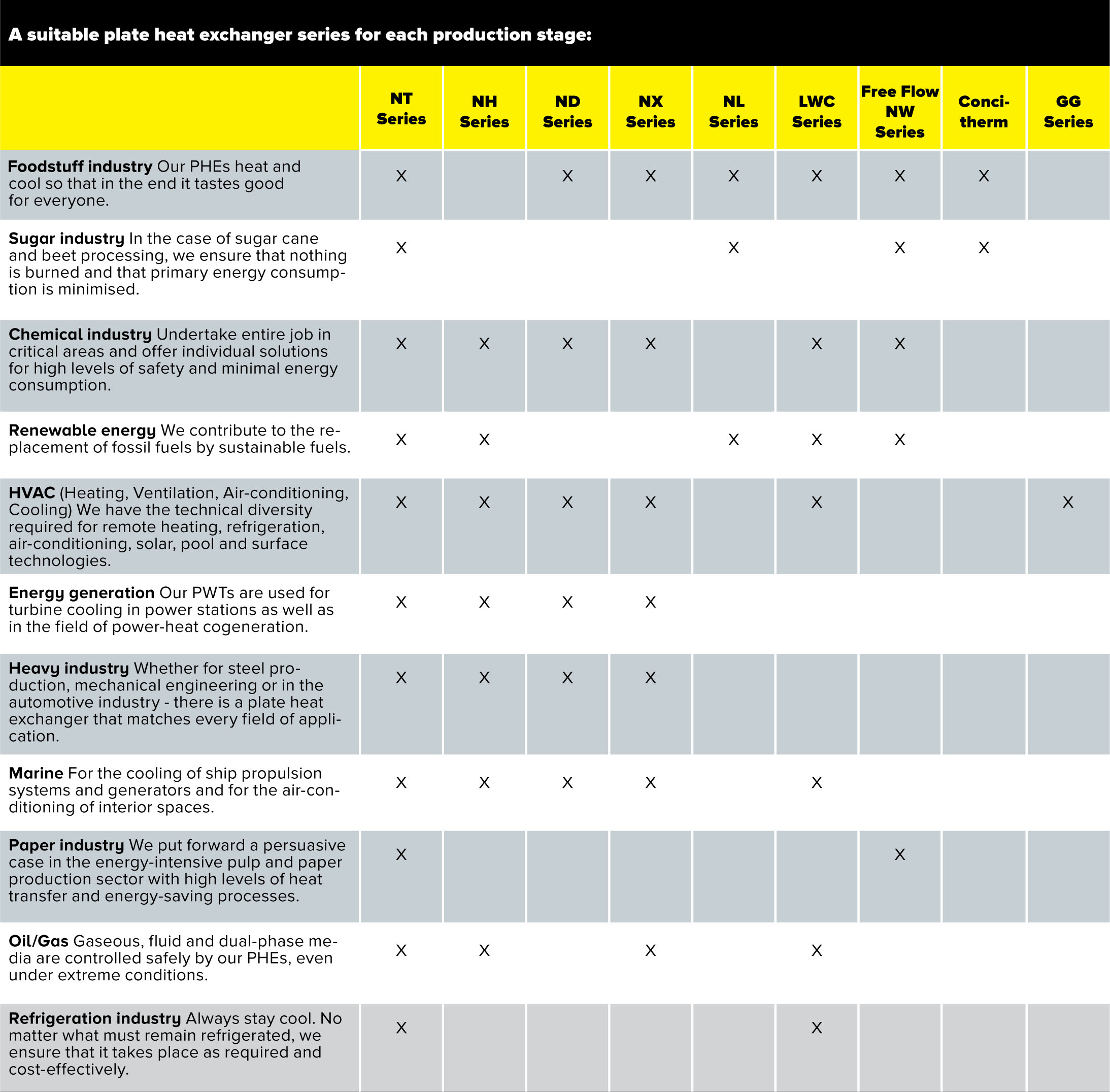

Performance Overview

The N Series - QUALITY AND FLEXIBILITY AT ITS BEST

You can benefit from the innovative technology of our gasketed plate heat exchangers no matter whether high pressure or harsh operating conditions. For tall buildings or for low investment , operating and service costs. For use with critical media or for high-performance remote refrigeration systems. Thanks to the technical characteristics and the ability to swap various plate series in the same frames, the N Series offers an extraordinarily broad spectrum of applications – in the broadest range of sectors and for the most diverse media.

N for high flexibility

Even if the medium or requirement changes. There is no greater flexibility: Nearly all of the N series can be used in the same frame and various plate numbers.

EcoLoc gasket system

Done in a matter of moments: Thanks to their glueless EcoLoc gaskets, they can be exchanged quickly and simply.

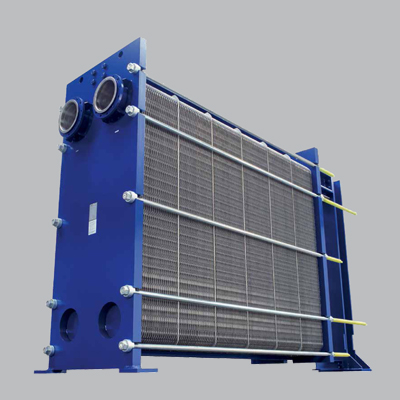

OptiWave design

Optimised corrugation leads to the highest heat transfer rates by means of the uniform distribution of media over the entire width of the plate.

PosLoc assembly

The PosLoc assembly system leads to a stable, perfectly aligned plate package. The gaskets lie exactly alongside each other and remain functional for longer.