WHY GEA PUMPS & SYSTEMS ?

- Every four liter of human blood is handled by GEA Equipments

- Globally Around One Quarter of the MILK Processed is handled by GEA Equipments

- Roughly every second liter beer is brewed using GEA Equipments & Solutions

- Approx one in three instant coffee lines is built by GEA

Hilge Hygienic Pumps sets high standards in the pump industry in terms of reliable operation, gentle product handling and hygienic design using high-quality stainless steel.

The GEA Hilge Model NOVATWIN can be used by customers in the milk and dairy, beverage, food, pharmaceutical, biopharmaceutical, pet food and personal care industries.

GEA Hilge pumps have a wide range of applications.

- In the dairy products sector, for example, cream cheese, butter, yoghurt (also with fruit pieces), sour cream and ice cream.

- In the food sector, these include sugar solutions, chocolate, sauces (also with pieces), soups, mayonnaise, pastes, oils and fats, ready-made salads and pet food.

- Good examples of beverages are smoothies, juice concentrates, premixes and brewing yeast.

- Applications in the sector Pharmaceuticals and biopharmaceuticals can include nutraceuticals, blood products, vaccines, enzymes and cell cultures. For personal care products and household cleaners, GEA Hilge NOVATWIN can be used in the manufacture, processing and filling of cosmetics, body and skin care, textile care and in the processing of household cleaners and the unique design was one, which none can be compared.

GEA Hilge NOVALOBE rotary lobe pump and the GEA Hilge NOVATWIN twin screw pump handle even the most sensitive products, such as blood plasma, gently and with low pulsation and shear forces. Both can be completely emptied of residues and are fully CIP/SIP-capable, which shortens production downtimes and thus has a positive effect on the operating company's revenue. In addition to product transfer, the pumps are also designed for use in CIP cleaning and SIP disinfection circuits. GEA pumps are supplied with comprehensive documentation to support the validation and FDA approval of pharmaceutical plants: Factory certificate/acceptance certificate according to 2.2 DIN EN 10204; material certificate according to 3.1 DIN EN 10204; FDA-USP Class VI certificate of conformity for the sealing and other materials used; surface roughness measurement report; ferrite content measurement report. All types are designed in accordance with the EHEDG guidelines.

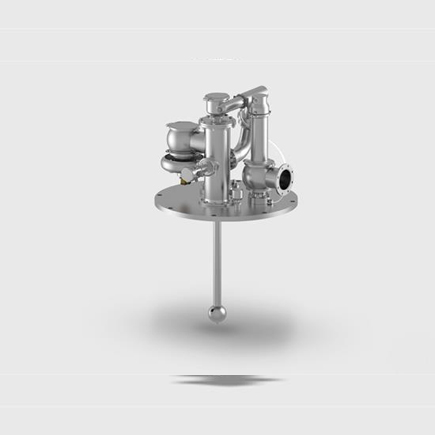

GEA Hygienic Valves

Hygienic valves from GEA form the core component of matrix-piped process plants. Thanks to a pioneering valve concept that sets standards for its flexibility, as well as the latest control and automation functions, our valves offer manufacturers maximum product safety and process reliability. All GEA hygienic valves are designed to be efficient and cost-effective for their applications, leading to sustainable operation and considerable savings potential.

GEA valve technology controls flow processes

Our hygienic valve technology ensures safe, efficient processes wherever sensitive liquid products are manufactured. In food production, the classic application areas range from milk processing to liquid foods and on to the brewing of beer and production of beverages. Further significant areas are biotechnology and pharmaceuticals, as well as care products and cleaning agents/detergents.

Regardless of the sector, the application or production specifications: Our hygienic valve technology is sure to meet the demands of our users.